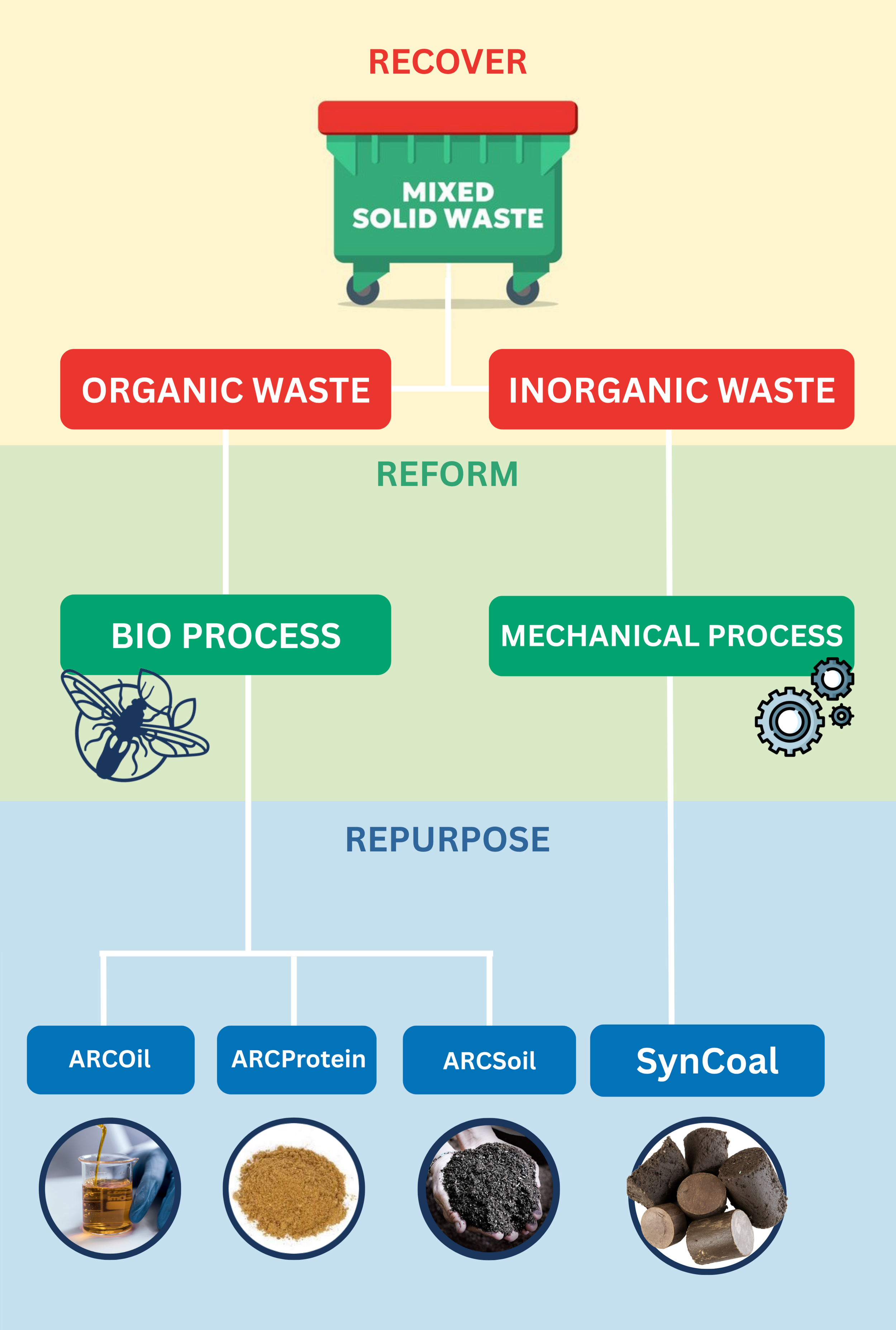

RECOVER

•

REFORM

•

REPURPOSE

•

RECOVER • REFORM • REPURPOSE •

BIO TECHNOLOGY

Nutrient Recovery

We harness the remarkable bioconversion capacity of the Black Soldier Fly (BSF) in a controlled, biosecure process. BSF larvae rapidly stabilise putrescible organics, even when commingled with non-organics, allowing us to separate contaminants, recover resources, and return nutrients to productive use. The result is a fast, low-emission pathway that diverts waste from landfill, reduces methane risk, and produces consistent, high-value outputs under robust quality management.

Value-Added Outputs

Insect Meal (Protein & Lipids): A high-quality ingredient suitable for formulated feed and material applications, produced to defined nutritional specifications.

Insect Frass Fertiliser: A biologically active soil amendment that supports nutrient-use efficiency and soil health, available in screened, flowable grades.

Bio-Oil: A versatile lipid fraction for energy or industrial uses, refined to align with downstream requirements.

Specialty Fractions for R&D: Purified components with potential pharmaceutical, nutraceutical, and biomaterial applications, developed in collaboration with accredited partners.

Together, these streams exemplify circular design, transforming problematic organic residues into reliable inputs for agriculture, industry, and innovation.

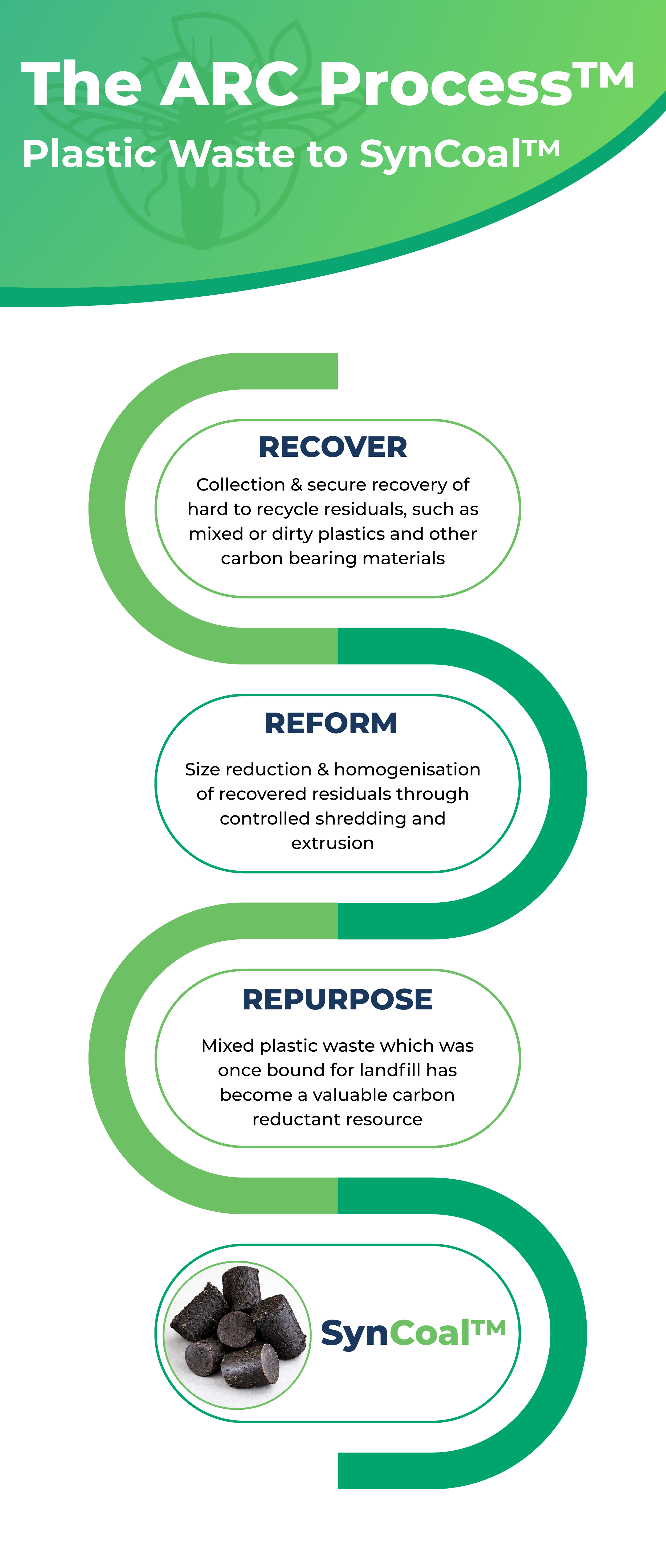

The ARC Process

Reshaping how we deal with and utilise waste

Working with Nature: Black Soldier Fly Bioconversion

MECHANICAL TECHNOLOGY

Industrial Engineering: SynCoal™ (Carbon & Hydrogen Recovery)

SynCoal™: A Sustainable Alternative to Coking Coal

Through our ARC Process™, residual waste streams, particularly hard-to-recycle plastics and selected inorganics are recovered, reformed, and re-purposed into SynCoal™, an engineered carbon-rich product. SynCoal™ provides a commercially viable source of carbon and hydrogen for industrial applications, offering a practical substitute for natural coal and hydrocarbons.

Key attributes

Feedstock flexibility: Utilises residual plastics and mixed solid waste fractions that are otherwise difficult to valorise.

Engineered performance: Tailored to meet downstream specifications for metallurgical reductants, process heat, and other industrial uses.

Circular outcomes: Diverts challenging materials from landfill and creates a reliable offtake pathway aligned with circular economy goals.

Together, our BSF bioconversion and SynCoal™ platforms demonstrate end-to-end resource recovery: organics back to soils and feeds, residuals into purposeful carbon and hydrogen, closing the loop with practical, scalable infrastructure.